Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Showing 13–24 of 30 results

-

Colmonoy® 53 HV

Nickel-Based Hard-Surfacing Alloys with Good Crack Resistance, Good Impact Resistance, and Moderate HardnessDESCRIPTIONProduced by intert gas atomization and can be spray deposited and fused to achieve a dense metallurgically bonded coating layer.APPLICATION METHODSHVOF/HVAFTYPESNickelWCC45-53 -

Colmonoy® 53F

Nickel-Based Hard-Surfacing Alloys with Increased Ductility, Better Impact Resistance, and Moderate HardnessDESCRIPTIONFor use on new parts to resist against wear, corrosion, heat, and galling. Also used for repair of work or out of tolerance parts.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL45-53 -

Colmonoy® 7303-60

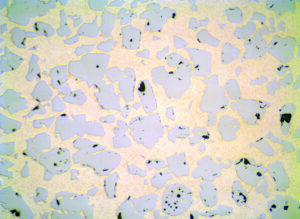

Nickel-Based Hard-Surfacing Composite Alloy for High Impact and Wear Resistance in PTA ApplicationsDESCRIPTIONThe combination of an extremely tough matric and very hard carbide produces an exceptional impact and wear resistance combinations.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal35-40 -

Colmonoy® 7303-65

Nickel-Based Hard-Surfacing Composite Alloy for High Impact and Wear Resistance in PTA ApplicationsDESCRIPTIONThe combination of an extremely tough matric and very hard carbide produces an exceptional impact and wear resistance combinations.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal30-40 -

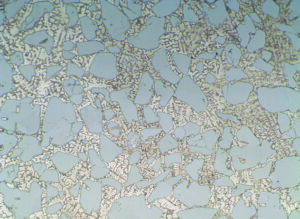

Colmonoy® 7602-20 M

Nickel-Based Spray & Fuse Composite Alloy with Excellent Tungsten Carbide Deposite EfficiencyDESCRIPTIONContains both crushed and atomized powders.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal57+ -

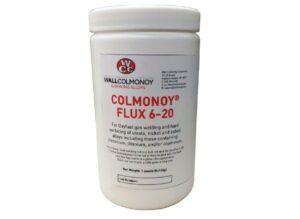

Colmonoy® Flux 6-20

Powder Flux for Use with Colmonoy® and Wallex® Continuous Cast or Sintered RodsDESCRIPTIONBase metals on which it is effectively used in include iron and nickel based alloys, including those containing chromium, titanium and/or aluminum. -

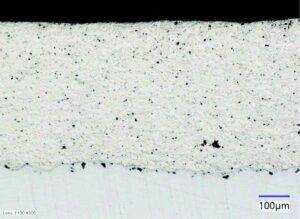

WallCarb™ 75/25

75% Chromium Carbide with 25% of Nickel/Chromium (80%/20%) PowderDESCRIPTIONDesigned for thermal spray applications, producing dense, wear-resistant coatings with excellent corrosion and oxidation resistance.APPLICATION METHODSHVOF/HVAFTYPESCarbideGlobal~900 HV -

WallCarb™ 80/20

80% Chromium Carbide with 20% of Nickel/Chromium PowderDESCRIPTIONDesigned for thermal spray applications, producing dense, wear-resistant coatings with excellent corrosion and oxidation resistance.APPLICATION METHODSHVOF/HVAFTYPESCarbideGlobal~900 HV -

WallCarb™ 90/10

Tungsten Carbide 10% Nickel Sintered Powder for application by High Velocity Thermal Spray ProcessesDESCRIPTIONDesigned for thermal spray applications, offering dense, hard coatings with low porosity and excellent wear and corrosion resistance.APPLICATION METHODSHVOF/HVAFTYPESCarbideGlobal>1,000 HV -

Wallex® 40

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal40-46 -

Wallex® 40 HV

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal40-46 -

Wallex® 40 PTA

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODSPTATYPESCobaltGlobal40-46