Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Showing 37–48 of 195 results

-

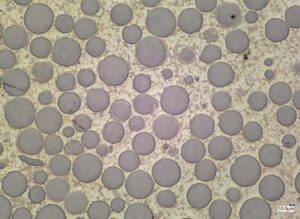

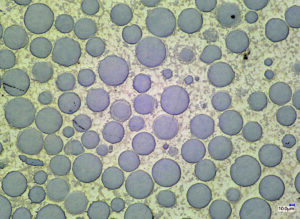

Colmonoy® 3001-604

Spherical Tungsten Carbide Powders in a Ni-Cr-B-Si-Fe-C MatrixDESCRIPTIONA blend using extremely hard and wear resistant spherical tungsten carbide.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal30 -

Colmonoy® 3001-654

Spherical Tungsten Carbide Powders in a Ni-Cr-B-Si-Fe-C MatrixDESCRIPTIONA blend using extremely hard and wear resistant spherical tungsten carbide.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal30 -

Colmonoy® 315

Nickel-Based Hard-Surfacing Alloy for Glass Mould and Other Cast-Iron or Alloy ComponentsDESCRIPTIONTypically used for glass mould components on new parts to resist against wear, corrosion, and oxidation at elevated temperatures and used for repair of worn or out of tolerance parts.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelWCL22-35 -

Colmonoy® 315P

Nickel-Based Hard-Surfacing Alloy Designed for Hardfacing Grey Cast IronDESCRIPTIONContains aluminium to absorb gases which may evolve during the welding process.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickel -

Colmonoy® 323

Low Melting, Premium Nickel-Based Hard-Surfacing Alloy for Application to Poor Quality Cast Iron and Steel Base MetalsDESCRIPTIONA low melting alloy with excellence wettability on cast irongs and bronze.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal20-25 -

Colmonoy® 33

Nickel-Based Hard-Surfacing Alloy for Glass Mould and Other Cast-Iron or Alloy ComponentsDESCRIPTIONTypically used for glass mould components on new parts to resist against wear, corrosion, and oxidation at elevated temperatures and used for repair of worn or out of tolerance parts.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelWCL22-35 -

Colmonoy® 3600

Nickel-Chromium-Molybdenum Powder for PTA & Laser Cladding with Low Magnetic PermeabilityDESCRIPTIONAlloy with moderate hardness and good toughness. It is highly suitable for combining with various hard metals for use in down hole applications where low magnetic permeability in important.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal36 -

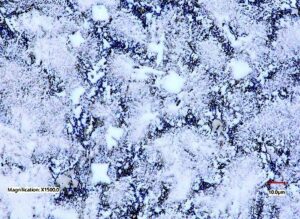

Colmonoy® 4

Nickel-Based Alloy for Hard-Surfacing of OEM Parts Restoring Worn Parts to Extend LifeDESCRIPTIONProduced by proprietrary atomization and crusting processes. This alloy is using for hard surfacing parts to resist wear, heat, corrosion, and galling.APPLICATION METHODSThermal Spray / Spraywelder™TYPESNickelGlobal35-44 -

Colmonoy® 4 A

Nickel-Based Alloy for Hard-Surfacing of OEM Parts Restoring Worn Parts to Extend LifeDESCRIPTIONProduced by proprietrary atomization and crusting processes. This alloy is using for hard surfacing parts to resist wear, heat, corrosion, and galling.APPLICATION METHODSThermal Spray / Spraywelder™TYPESNickelGlobal35-44 -

Colmonoy® 4 L

Nickel-Based Alloy for Hard-Surfacing of OEM Parts Restoring Worn Parts to Extend LifeDESCRIPTIONProduced by proprietrary atomization and crusting processes. This alloy is using for hard surfacing parts to resist wear, heat, corrosion, and galling.APPLICATION METHODSLaser CladdingTYPESNickelGlobal35-44 -

Colmonoy® 4 PTA

Nickel-Based Alloy for Hard-Surfacing of OEM Parts Restoring Worn Parts to Extend LifeDESCRIPTIONProduced by proprietrary atomization and crusting processes. This alloy is using for hard surfacing parts to resist wear, heat, corrosion, and galling.APPLICATION METHODSPTATYPESNickelGlobal35-44 -

Colmonoy® 40 M

Nickel-Based Alloy for Hard-Surfacing of OEM Parts Restoring Worn Parts to Extend LifeDESCRIPTIONProduced by proprietrary atomization and crusting processes. This alloy is using for hard surfacing parts to resist wear, heat, corrosion, and galling.APPLICATION METHODSThermal Spray / Spraywelder™TYPESNickelGlobal35-44