Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Showing 181–192 of 195 results

-

Wallex® 40 PTA

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODSPTATYPESCobaltGlobal40-46 -

Wallex® 42H

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal45-50 -

Wallex® 42M

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal45-50 -

Wallex® 42SA

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal45-50 -

Wallex® 50

Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONIs most suitable for metal-to-metal wear protection in corrosive environment where impact is not substantial.APPLICATION METHODSThermal Spray / Spraywelder™TYPESCobaltGlobal55-61 -

Wallex® 50 HV

Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONIs most suitable for metal-to-metal wear protection in corrosive environment where impact is not substantial.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal55-61 -

Wallex® 50 L

Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONIs most suitable for metal-to-metal wear protection in corrosive environment where impact is not substantial.APPLICATION METHODS- Laser Cladding

- PTA

TYPESCobaltGlobal55-61 -

Wallex® 50 PTA

Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONIs most suitable for metal-to-metal wear protection in corrosive environment where impact is not substantial.APPLICATION METHODS- Laser Cladding

- PTA

TYPESCobaltGlobal55-61 -

Wallex® 55

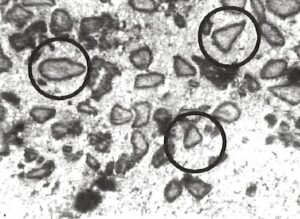

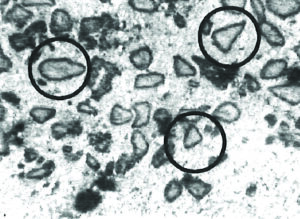

Cobalt-Based Composite Hard-Surfacing Alloy with High-Abrasion and Corrosion ResistanceDESCRIPTIONContains both atomized and crushed powders and is enriched with extremely hard tungsten carbide particles.APPLICATION METHODSThermal Spray / Spraywelder™TYPESCobaltGlobal58+ -

Wallex® 55 HV

Cobalt-Based Composite Hard-Surfacing Alloy with High-Abrasion and Corrosion ResistanceDESCRIPTIONContains both atomized and crushed powders and is enriched with extremely hard tungsten carbide particles.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal58+ -

Wallex® 6

Cobalt-Based Alloy with Excellent Resistance to Erosion and CavitationDESCRIPTIONContains chromium, tungsten, and carbon to form hard phase carbides, to resist against wear, corrosion, heat, galling, erosion, and cavitation.APPLICATION METHODS- HIPping (Hot Isostatic Pressing)

- HVOF/HVAF

- Laser Cladding

- PTA

TYPESCobaltGlobal38-46 -

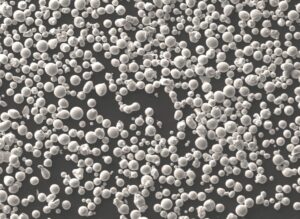

Wallex® ASTM F75 CoCrMo

Cobalt-Chromium Additive Manufacturing Powders for Biomedical Applications, such as Orthopedic and Dental implants for use with CAD/CAM Ceramic ApplicationsDESCRIPTIONOffers maximum flexibility and compatibility with a wide range of ceramics, thanks to their optimal coefficient of linear thermal expansion.APPLICATION METHODSAdditive ManufacturingTYPESCobalt