Pumps & Valves

Alloys that Keep You Flowing

Across a range of industrial environments, pumps and valves are expected to deliver dependable, long-term performance. Colmonoy® nickel-based, Wallex® cobalt-based, Colferoloy™ iron-based and WallCarb™ surfacing alloys are engineered for applications exposed to abrasive or erosive fluids, high-temperature environments, or corrosive chemicals – extending service life and ensuring consistent flow performance.

Our alloys protect critical components such as valve seats, stems, pump casings, impellers, and shafts. With decades of metallurgical expertise, we understand the challenges of flow control. Our proven solutions minimize wear, reduce maintenance, and keep systems operating smoothly and efficiently.

Products & Applications

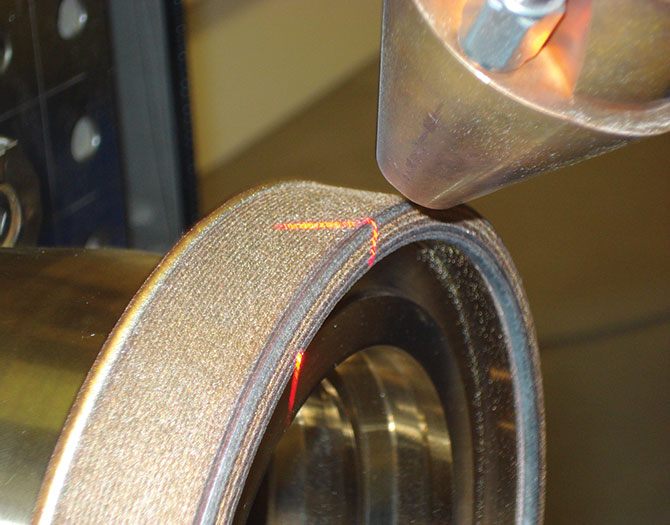

Colmonoy®, Wallex®, Colferoloy™ and WallCarb™ alloys are widely used to repair worn parts or coat new components such as pump sleeves, valve seats, impellers, casings, wear rings, shafts, and bearings.

Designed to withstand severe wear and erosion, they deliver proven performance in demanding industries including mining, oil & gas, and chemical processing.

Application Methods

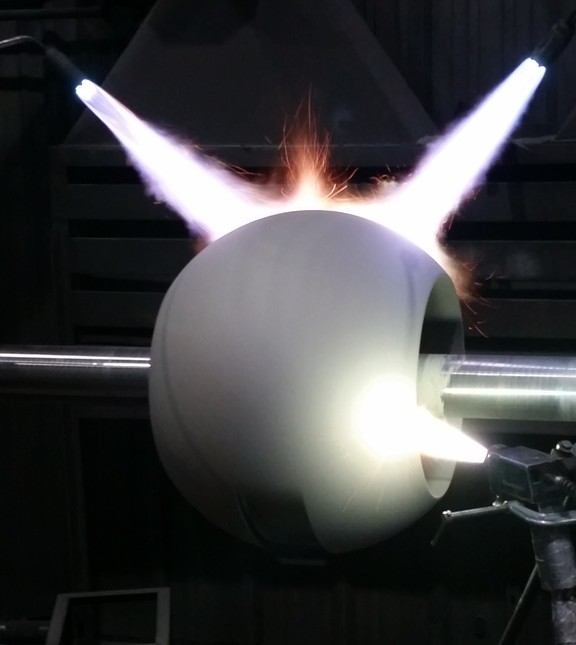

Whether applying a thin, high-performance coating or rebuilding worn parts for renewed service, Wall Colmonoy delivers dependable results across thermal spray, welding, cladding, and powder welding techniques.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.