Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Showing 1–12 of 15 results

-

Colferoloy™ SS 420

Martensitic Stainless Steel Powder for PTA, Laser, HVOF, and AM ApplicationsDESCRIPTIONHigh-hardenable martensitic stainless stell containing 12% minimum Cr level.APPLICATION METHODS- Additive Manufacturing

- HSLC (High Speed Laser Cladding)

- HVOF/HVAF

- Laser Cladding

- PTA

TYPESIronGlobal96 HRB -

Colmonoy® 64

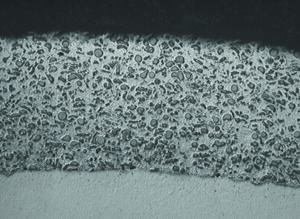

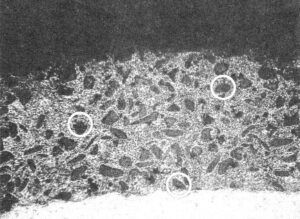

40% Agglomerated Tungsten Carbide in a Ni-Cr-B Matrix for All Combusion Thermal Spray SystemsDESCRIPTIONA unique composite material containing a moderately high volume percent of extremely abrasion resistant tungsten carbide particles in an abrasion resistant nickel-based matrix alloy.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal58+ -

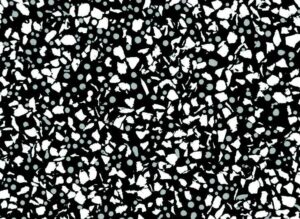

Colmonoy® 750

Ni-Cr-B-W Composite Hard-Surfacing Alloy with High Abrasion and Corrosion ResistanceDESCRIPTIONContains both atomized and crushed powders. It is enriched with extremely hard, virgin tungsten carbid particles ideally shaped and sized for optimum performance.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelGlobal57-63 -

Colmonoy® 7631-60F

Nickel-Based Hard-Surfacing Ally for Fuseweld™ ApplicationDESCRIPTIONProvides a tough, metal to metal wear resistance deposit that is ideally suited to abrasion by fine to medium particles.APPLICATION METHODSFusewelder™ TorchTYPESNickelGlobal59 -

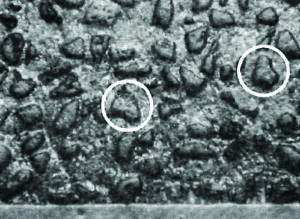

Colmonoy® ColTung 1 Rod

Nickel-Based Hardfacing Rod with Tungsten Carbides for High Abrasion, Oxidation, Corrosion and Impact ResistanceDESCRIPTIONHas excellent resistance to severe sliding abrasion.APPLICATION METHODSHardfacing RodTYPESNickelGlobal59-64 -

Colmonoy® Flux 6-20

Powder Flux for Use with Colmonoy® and Wallex® Continuous Cast or Sintered RodsDESCRIPTIONBase metals on which it is effectively used in include iron and nickel based alloys, including those containing chromium, titanium and/or aluminum. -

Wallex® 40

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal40-46 -

Wallex® 40 HV

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal40-46 -

Wallex® 40 PTA

Self-Fluxing Cobalt-Based Hard-Surfacing Alloys with High Corrosion and Impact ResistanceDESCRIPTIONBetter impact resistance and are non-toxic and non-forgeable.APPLICATION METHODSPTATYPESCobaltGlobal40-46 -

Wallex® 42H

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODSHVOF/HVAFTYPESCobaltGlobal45-50 -

Wallex® 42M

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal45-50 -

Wallex® 42SA

Self-Fluxing Cobalt-Based Hard-Surfacing Alloy Powder with High Corrosion and Impact ResistanceDESCRIPTIONHave excellent red hardness and superior wettability.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESCobaltGlobal45-50