Find Your Powder

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Filter Results

Found materials matching your search input.

Our Hardfacing Product Finder tool quickly identifies the ideal solution based on industry, application, and performance requirements.

Showing 1–12 of 44 results

-

Colmonoy® 4001-50 Wire

Nickel-Based Metal Cored Wire With Tungsten Carbide for Improved Wear ResistanceDESCRIPTIONA metal cored wire with deposits that consist of a tough nickel base matrix and exhibit good crack resistance.APPLICATION METHODSHardfacing WireTYPESNickel -

Colmonoy® 56 L

Nickel-Based Hard-Surfacing Alloys to Resist Abrasion, Corrosion, Heat and GallingDESCRIPTIONHigh levels of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Hardfacing Rod

- Hardfacing Wire

- Laser Cladding

TYPESNickel -

Colmonoy® 56 PTA

Nickel-Based Hard-Surfacing Alloys to Resist Abrasion, Corrosion, Heat and GallingDESCRIPTIONHigh levels of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Hardfacing Rod

- Hardfacing Wire

- PTA

TYPESNickel -

Colmonoy® 56 SPL PTA

Nickel-Based Hard-Surfacing Alloys to Resist Abrasion, Corrosion, Heat and GallingDESCRIPTIONHigh levels of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Hardfacing Rod

- Hardfacing Wire

- PTA

TYPESNickel -

Colmonoy® 56 Wire

Nickel-Based Metal Cored Wire With High Crack Resistance For Fast On-Site ApplicationDESCRIPTIONA metal cored wire. Available as 1/16" (1.6mm) diameter wire and are generall preferred for application by GMAW or MIG.APPLICATION METHODSHardfacing WireTYPESNickel -

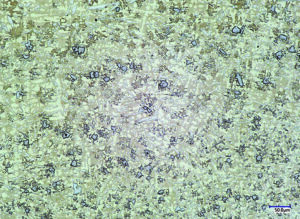

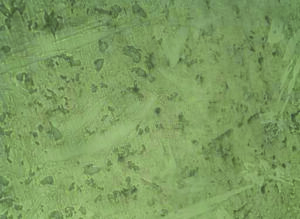

Colmonoy® 56C

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL50-55 -

Colmonoy® 56F

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODSFusewelder™ TorchTYPESNickelWCL50-55 -

Colmonoy® 56M

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL50-55 -

Colmonoy® 56P

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Hardfacing Rod

- Hardfacing Wire

- Laser Cladding

- PTA

TYPESNickel -

Colmonoy® 56SA

Nickel-Based Hard-Surfacing Alloy to Resist Abrasion, Corrosion, Hear and GallingDESCRIPTIONHigh levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance.APPLICATION METHODS- Fusewelder™ Torch

- Thermal Spray / Spraywelder™

TYPESNickelWCL50-55 -

Colmonoy® 57 PTA

Unique Ni-CR-B-W Hard-Surfacing PTA Alloy Designed for New and Rebuild Extrustion or Injection Molding ScrewsDESCRIPTIONContains optimized amounts of precipitated tungsten rich hard phases distributed throughout the matrix.APPLICATION METHODS- Laser Cladding

- PTA

TYPESNickelGlobal52-57 -

Colmonoy® 62 DJ

Nickel-Based Hard-Surfacing Alloy for Wear, Corrosion, Heat, and Galling ResistanceDESCRIPTIONUsed for hardsurfacing new parts to resist wear, corrosion, heat and galling. Also used for repair of worn or out of tolerance parts.APPLICATION METHODSHVOF/HVAFTYPESNickelWCC56-63