Laser Cladding Powders

Precision Deposition. Superior Protection. Lasting Performance.

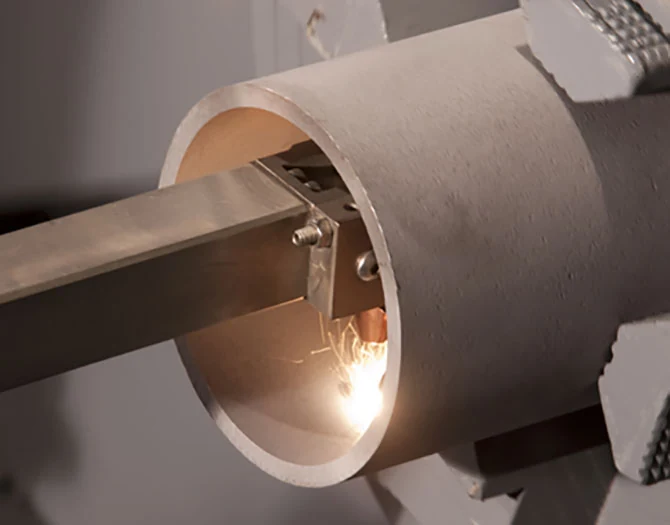

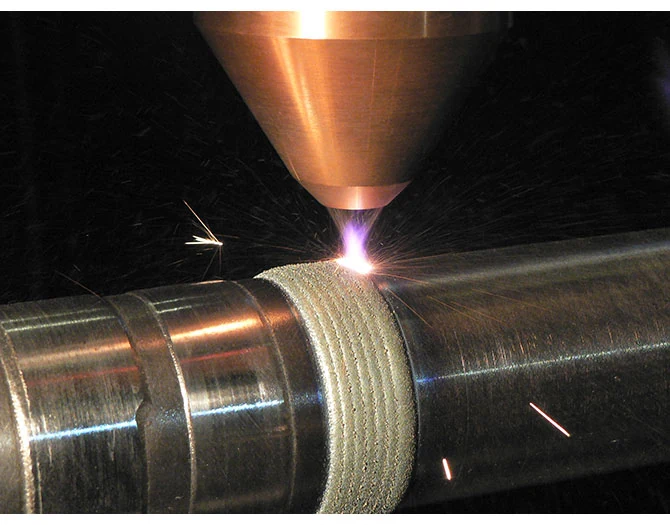

Laser cladding is a highly consistent and repeatable, automated process that produces metallurgically bonded coatings with minimal dilution and a negligible heat-affected zone (HAZ). This is due to its localized, short-duration, high-energy molten pool, which provides a rapid heating and solidification rate promoting a finer grain structure. This allows for the precise deposition of tough, wear-resistant materials that significantly enhance performance and durability.

This advanced surfacing technique is ideal for high-value parts that demand tight tolerances and corrosion or abrasion protection. Applications include superheater tubes, boiler tubes, panels, and coal nozzles in waste-to-energy; pump shafts, rods, couplings, valves, seats, and downhole drilling tools such as stabilizers and sleeves in oil & gas; continuous caster rolls in steel production; extrusion screw flights for injection molding; aerospace turbine blades and components; glass container industry neck rings and molds, and more.

Products for Laser Cladding

Wall Colmonoy offers a wide range of Colmonoy® nickel-, Wallex® cobalt-, and Colferoloy™ iron-based powders formulated for laser cladding and high-speed laser cladding, available in tailored particle size distributions and alloy chemistries. These powders provide dense, defect-free overlays with superior resistance to wear through impact, abrasion, and corrosion – even in extreme environments.

Whether you’re developing a new process or optimizing an existing one, our powders deliver reliable results for high-performance coating applications.

Technical Resources

Brochures and selector charts are available to the right. To search for a product, Safety Data Sheet or Case Studies, visit our Resource Library.

Get an overview of our surfacing alloys engineered to extend component life and performance.

Get an overview of our laser cladding powders for various industries and applications.

Use this chart to select alloys optimized for laser cladding and other processes.

Access alloy data and guidance for use in PTA welding and laser cladding methods.