Glass Container

Protecting and Restoring Glass Container Parts

For over 80 years, Wall Colmonoy’s Colmonoy® nickel-based and Wallex® cobalt-based surfacing alloys have set the standard for protecting and restoring glass container components.

Glass moulds endure heat, abrasion, and corrosion that shorten service life. Our surfacing alloys extend the life of neck rings, plungers, baffles, bottom and guide plates and more, reducing wear and enabling quick repairs – helping manufacturers cut downtime, lower costs, and increase throughput.

Products & Applications

Our materials are used to protect and restore glass parts such as baffles, neck rings, guide plates & guide rings, plugs, blow heads, funnels, plungers – blow-and-blow, press-and-blow, pressware, narrow-neck, ensuring longer service life, consistent container quality, and reliable production output for glassmakers worldwide.

Application Methods

Wall Colmonoy offers a range of alloys and formulations to suit a variety of glass applications and production environments.

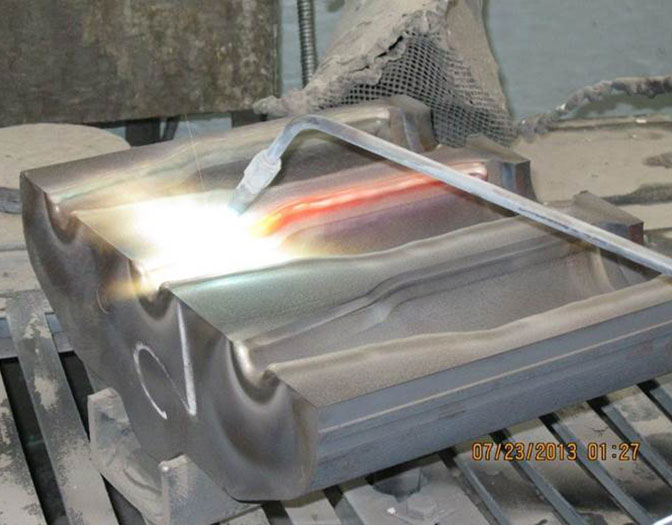

Wall Colmonoy also designs the Spraywelder™ System and Fusewelder™ Torch – purpose-built for reliable, efficient powder application.

OFW (Oxy-fuel Welding), GMAW (MIG), and GTAW (TIG)

Latest News, Events & Case Studies

Explore the latest news, events, and real-world applications showcasing how Wall Colmonoy delivers solutions to customers’ wear challenges.