Hardfacing Wires & Rods

Proven Hardfacing Protection

Colmonoy® rods and wires are trusted across industries for both new-build protection and spot repairs, from extrusion screws, pump shafts, and camshafts to agricultural tools, hammers, blades, and other high-wear components.

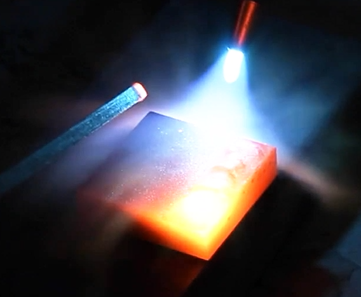

Applied using the techniques of OFW (Oxy-fuel Welding), GMAW (MIG) for wires, and GTAW (TIG) for rods, Colmonoy® forms metallurgically bonded weld overlays that deliver wear and corrosion resistance – reducing costly downtime and keeping equipment in operation longer.

Products for Hardfacing Wire & Rod Applications

Wall Colmonoy’s cored wires – including Colmonoy® 56, 88, 4001-50 – offer high wear resistance and minimal dilution for clean, efficient surfacing. Our bare rods are available as sintered or continuous cast in a range of diameters, suitable for both TIG welding and flame application, delivering excellent deposit efficiency and ease of use – heating only the part being coated and no equipment needed.

Technical Resources

Brochures and selector charts are available to the right. To search for a product, Safety Data Sheet or Case Studies, visit our Resource Library.

Review technical specifications and performance properties of Colmonoy® hardfacing rods.

Access detailed data on Colmonoy® 56 and 88 wires for demanding applications.

See performance and application details for Colmonoy® 4001-50 wire alloys.